Our Products

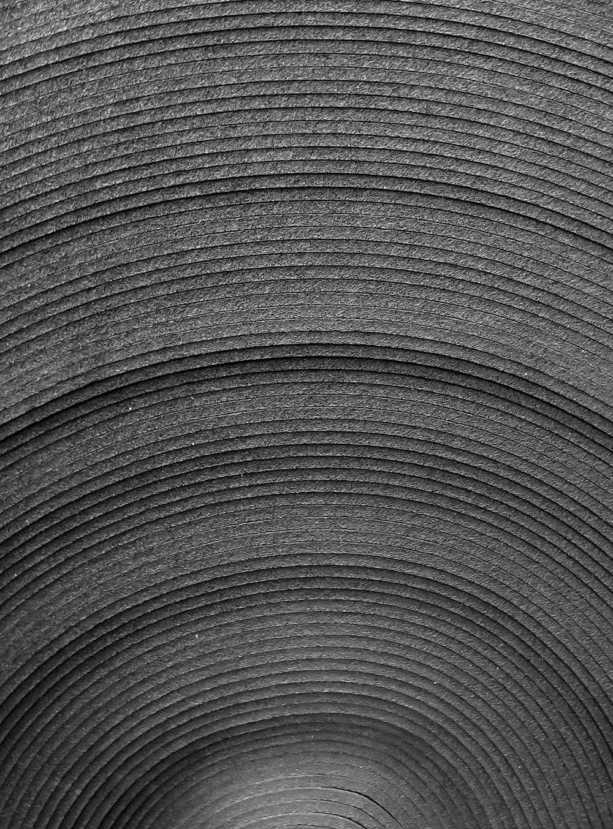

Polyfill Acoustical Barrier

Polyfill’s base chemistry acoustical barrier begins as raw materials drawn from bulk storage by a computer controlled batching system, which delivers lot-to-lot consistency, along with the flexibility to custom blend to meet unique customer requirements.

Both our calendering line and direct extrusion line with flex-lip die provide a wide range of surface weights and widths in either rolled goods or specified dimensional sheets via a precise and highly automated process. Polyfill also offers a number of ancillary operations that add value to the our material. Each production line is capable of laminating films, fabrics, web adhesives, and carpets. Our acoustical barrier material can also be subjected to flame treatment to enhance adhesion to laminates and other substrates that may be added during a downstream process at the customer’s location.

Want to learn more?

Contact us and a Polyfill representative will be in touch with you within 24 hours.

Product Highlights

Simple and Low-Cost Noise Solution

In-Line Lamination to Multiple Substrates

Low Cost-To-Weight Ratio for Barrier Applications

Recyclable

Thermoformable

Custom Blending

Our Products

Laminate and De-Coupler Options

- Foam

- Fiber

- Web adhesives

- Scrims

- Shoddy

- Aluminum Foils

- Films

- Tufted Carpets

- Nonwoven Carpets

Material Properties

- Weight/area range: 0.2lbs/ft2 - 2.0Lbs/ft2

- Specific gravity range: 1.2g/m3 - 2.8g/m3

- Passes many manufacturers requirements for flammability, including FMVSS 302

- EVA SDS (Download PDF)

- EVA Stabilized SDS (Download PDF)

- Filled PE Barrier SDS (Download PDF)

- Passes VDA 278 for VOC emissions

Sustainability

Polyfill's acoustical barrier is virtually 100% recyclable. You can even find our recycled product used in such applications as garden mulch and playground surface covering. Trim that may otherwise be considered waste for disposal can become part of a regrind program that helps control costs for both the customer and supplier.

Quality

Polyfill's product is a proprietary blend of ethylene-based copolymers and other constituents designed to achieve the necessary surface weight and processability for performance in specific applications. Polyfill validates material in process, line side, and post process in our quality assurance labs. Our quality department tests physical characteristics certified to applicable specifications and provides PPAP packages.